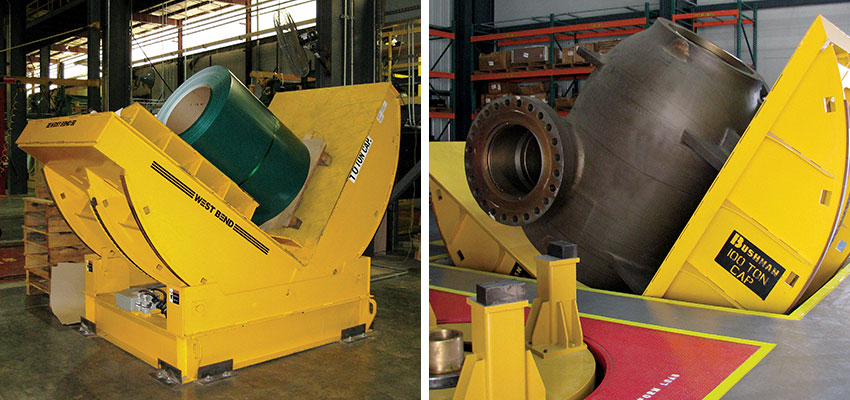

The Bushman Equipment, Inc. mechanical upender provides an easy and efficient way to upend metal coils, molds, dies and other heavy and bulky loads. Mechanical upenders, sometimes called coil positioners, rotate steel, aluminum & other non-ferrous coils and other loads through 90 degrees. They are used in a variety of production and maintenance applications.

Capacities are available up to 200 tons along with a variety of options.

Mechanical upenders are available in standard configurations or may be custom engineered for your particular application.

Mechanical upenders have a 3/4 round-shaped cradle that is placed on four machined steel rollers. An electric-powered gear motor driving a single or dual chain sprocket provides the ability to rotate.

Left: Single chain

Center: Double chain

Right: Double-wide chain may be used

Single or double drive chains dependent on capacity and location of load’s center of gravity.

Single or double drive chains dependent on capacity and location of load’s center of gravity.

Left: Flat tread steel wheel

Right: Fixed axle supported on both sides

Welded steel trucks with four straight tread, single flanged steel wheels with roller bearings.

Welded steel trucks with four straight tread, single flanged steel wheels with roller bearings.

Fully enclosed right angle drive gearbox with single speed motor and disc brake. Output drive open gearset is guarded.

Fully enclosed right angle drive gearbox with single speed motor and disc brake. Output drive open gearset is guarded.

Left: Locking pin for maintenance

Right: Lifting lugs for easy positioning

The platforms of the upender cradle not only support the load, but are designed to interface with the handling device that sets or removes the load.

The basic cradle has two flat platforms.

The basic cradle has two flat platforms.

Left: Coil in V-saddle

Right: UHMW pads

For coil handling, the coil rests on a welded steel V-saddle. The surface of the saddle can be bare steel, or covered with replaceable UHMW or Nylatron pads.

For coil handling, the coil rests on a welded steel V-saddle. The surface of the saddle can be bare steel, or covered with replaceable UHMW or Nylatron pads.

Left: Nylatron pads

Right: Bonded urethane with motorized V-saddle

A motorized V-saddle (above right) can gently move a coil and snug it up to the pallet before tipping. This prevents the coil from sliding while it is tipped.

A motorized V-saddle (above right) can gently move a coil and snug it up to the pallet before tipping. This prevents the coil from sliding while it is tipped.

A motorized pallet adjuster helps to center the coil when tipping a wide range of coil diameters.

A motorized pallet adjuster helps to center the coil when tipping a wide range of coil diameters.

Left: C-hook slot

Right: Cutout for coil grab

When loading a coil with a crane using a c-hook or motorized coil grab, a slot and/or cutout is needed for interfacing with the upender.

When loading a coil with a crane using a c-hook or motorized coil grab, a slot and/or cutout is needed for interfacing with the upender.

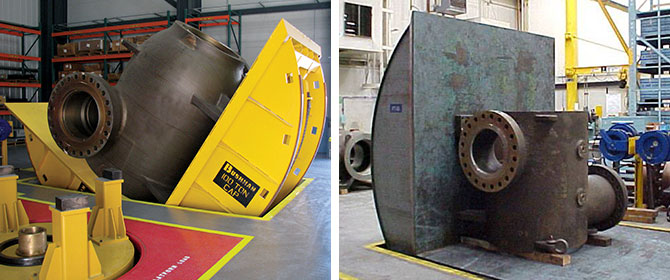

Structural set offs can be used to support uniquely shaped loads.

Structural set offs can be used to support uniquely shaped loads.

Left: Heavy roller conveyor

Right: Light roller conveyor

Ball transfer rollers

Conveyors & ball transfer rollers may be used to load and unload the upender.

Conveyors & ball transfer rollers may be used to load and unload the upender.

Pit mounted upenders allow the platforms to be flush with the floor to facilitate loading or worker interface.

Pit mounted upenders allow the platforms to be flush with the floor to facilitate loading or worker interface.

Leveling pads can be provided to ensure a near perfect level platform.

Leveling pads can be provided to ensure a near perfect level platform.

A motorized rotating base is used when loading and unloading with a fork truck. The truck does not have to reposition itself after the load is tipped.

A motorized rotating base is used when loading and unloading with a fork truck. The truck does not have to reposition itself after the load is tipped.

An upender can be mounted onto a weigh system stand.

Steel mill upenders tip coils for an annealing process.

Steel mill upenders tip coils for an annealing process.

Note T-slots for tie-down of load.

These upenders tip plastic injection molds for clean out and maintenance.

These upenders tip plastic injection molds for clean out and maintenance.

This upender is used for specialized machine assembly. It has manually adjustable V-saddles.

This upender is used for specialized machine assembly. It has manually adjustable V-saddles.

25,000 lb capacity upender with machined loading platform.

10 metric ton coil upender, pit mounted, with a motorized V-saddle & motorized pallet adjuster.

80 metric ton upender holds utility transformer coils on a cantilevered arm.